A comprehensive system of production management has been developed to ensure that high-quality products are supplied in a stable manner.

Gas sensors may vary in quality with changes in temperature and humidity experienced during manufacture. To maintain a constant quality level is extremely difficult, requiring considerable knowhow and management. Figaro is able to guarantee high quality products with its thorough production management system and its superior inspection system.

Quality policy

- Figaro Engineering Inc. is dedicated to fostering a sustainable social environment and a safe, secure, and comfortable life for people around the world through our proprietary gas sensing technology.

- We respect the basic principles of manufacturing (Monozukuri) that are specific to gas sensors, and we are committed to ongoing improvement through our own quality management system. We will strive to realize a higher level of quality chain, including upstream suppliers and downstream customers.

The quality assurance process

Figaro has introduced the ISO9001 quality management system into its operations. Any manufacturer must deal with defective products. The recurring question is how to reduce the number of defective products from the manufacturing process to as close to zero as possible. To achieve this goal requires engagement by the entire company across sales, development, manufacturing, and quality assurance divisions.

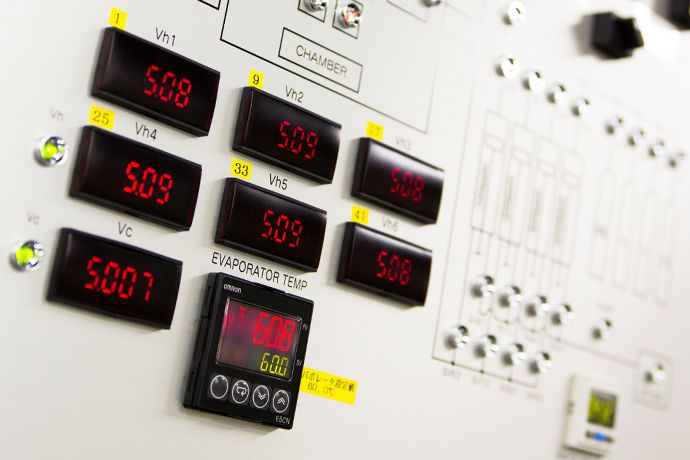

The manufacturing process

While the gas sensor is an electronic device, even if the same process is used for manufacture, differences in temperature and humidity between manufacturing plants may result in variations in quality. Figaro has focused on building a uniform manufacturing environment so that quality can be maintained despite variations in the factors affecting product quality (e.g. weather). Furthermore, modifications have been applied to the mixing of materials and fabrication processes to ensure that stable quality is maintained through both the manufacturing environment and the manufacturing process.

Daily variance report meetings are held as a means of preventing the occurrence of defects in the manufacturing process, with an unrelenting focus on sharing information about changes and abnormalities in the production line, determining causes, and implementing countermeasures to improve quality.

Quality inspection

Gas sensors are electronic devices in direct contact with air. Exposure to the air implies ready exposure to the effects of the local environment. Under these conditions, deterioration of performance and quality of defective components is unavoidable.

To provide customers with quality, reliable products, Figaro runs each product through a battery of tests following manufacture. To ensure that defects can be eliminated prior to shipping, Figaro will also subject some of its products to testing that goes beyond standard inspection tests.

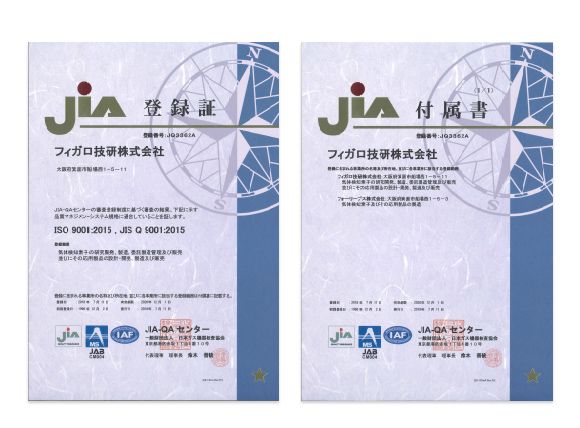

Authentication in quality management

ISO9001 (Quality management system)

An international management standard regulating the quality improvement of supplied products and services through maintenance and improvement of administrative processes to offer high quality products and services continuously.