In the early 1960s, the number of gas explosion accidents

was sharply increasing in Japan as the gas supply

infrastructure was being enhanced.

Naoyoshi Taguchi, the founder of Figaro Engineering Inc.,

became acutely aware of the need for gas detectors.

He strongly felt that the development of gas sensors had to be hastened.

After a few years of intensive research and experiments, he

finally found tin dioxide (SnO2) as a functional material

for gas detection, and completed a prototype of

a metal oxide semiconductor (MOS) type gas sensor.

Product timeline

Product images are representative of the products in the series, regardless of the actual time order year they were launched.

The first MOS-type

gas sensor

Mass production and sales of gas sensors began as a private business.

Taguchi developed a MOS-type gas sensor that can detect combustible gases and reducing gases with a simple circuit. Together with his high-school classmates, he began commercialization of the gas sensors under the trade name TGS (Taguchi Gas Sensor) for incorporation into residential gas detectors in Japan as well as other countries.

Mr. Naoyoshi Taguchi, the founder of the company

He graduated from Nagata High School in Hyogo Prefecture, enrolled at the Osaka Institute of Technology, and subsequently became involved in development work of gas sensors.

Foundation of Figaro Engineering Inc.

Taguchi, who was an avid fan of opera, named the company Figaro with the intention to reflect his vitality, enthusiasm and curiosity, just like Figaro, the main character of Rossini's opera "The Barber of Seville".

MOS-type gas sensors driven by 5VDC

Factory and Laboratory established in Toyonaka City, Osaka.

A solid position established in the gas sensor industry

The company was picked by the mass media as a leading venture company, and became a popular company, with the ratio of applications from students exceeding 100 times. The company also gained credibility as a leading manufacturer of gas sensors through quick development of countermeasures against false alarms by improving gas sensing materials and filters.

Manufacturing Technology Laboratory (Esaka factory) established in Suita City, Osaka

The first MOS-type CO sensor which can meet performance requirements of the technical standards for residential CO detectors

Awarded the Tanahashi Award of The Electrochemical Society of Japan

The company received the Tanahashi Award of the Electrochemical Society of Japan as the electrochemistry and industrial physics based technology development enterprise for "Development of Semiconductor Gas Sensors".

North American Office established. (reorganized as Figaro USA, Inc. in 1983)

In anticipation of future overseas expansion, the North American Office was established in Illinois, USA. This US office would later function as a base for global expansion.

FIGARO USA, Inc (photo: present building)

Head office and factories moved to Minoo city, Osaka

The company purchased a building in the Minoo Textile Complex and relocated the head office and factories. With the facilities and environment in hand to meet the needs of society, the company began to build a world-class mass production system.

The head office building in the Minoo Textile Complex (photo: present building)

Acquisition of the company by Tokuyama Soda Co., Ltd. (Tokuyama Corporation today)

Awarded the Technology Award of the Chemical Society of Japan

Figaro received the Technology Award of the Chemical Society of Japan for ”Development and industrialization of SnO2 sintered semiconductor gas sensor”.

Taguchi, Chiba, Iokura and their wives, and Takahata at the Awards ceremony

A joint venture Riken Figaro, Inc. established

A joint venture with RIKEN KEIKI Co., Ltd. was established in Sakurai City, Nara, to expand sales of gas sensor application products.

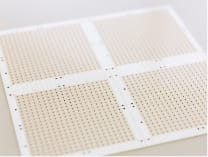

MOS-type one-side screen-printed gas sensor

MOS-type double-sided screen-printed gas sensor

Pulse heating MOS-type gas sensor

A joint venture TIANJIN FIGARO ELECTRONIC CO., LTD. established

At a time when Japanese manufacturers were not making many inroads into the Chinese market, the company established a Japan-China joint venturein Tianjin, China, which was rare at the time, and aggressively entered the Chinese market, believing that it would be a base for expansion into Asian market in terms of production and sales.

TIANJIN FIGARO ELECTRONIC CO., LTD. (photo: present building)

Starting export sales of oxygen sensors manufactured by Japan Storage Battery Co., Ltd. (GS Yuasa Corporation today)

Beginning of legislation for installation of residential CO alarms in the United States

Legislation to mandate the installation of carbon monoxide alarms was introduced in some U.S. states, leading a sharp increase in orders for TGS203. After 14 years since the establishment of the North American office, overseas business development gained momentum.

TGS20 series MOS-type gas sensors launched

The development of new sensing elements based on thick-film printing technology has led to miniaturization and reduced power consumption as well as a significant increase in production capacity, expanding a market from the safety field to the control and comfort field as air quality sensors.

The gas sensor elements manufactured by using the thick-film printing technology in the company's own way of application

Breath alcohol tester model KAC-80 launched

Figaro's first breath alcohol tester with its own brand name

ISO9001 certification achieved, strengthening its quality management system

Versatile MOS-type gas sensor

Combustible gas sensor module using TGS26 series

The first electrochemical type CO gas sensor

A joint venture SHANGHAI SONGJIANG FIGARO ELECTRONICS., LTD. established

A joint venture SHANGHAI SONGJIANG FIGARO ELECTRONICS., LTD. was established in Shanghai, China for production and sales of gas detectors for Chinese market.

SHANGHAI SONGJIANG FIGARO ELECTRONICS., LTD. (photo: present building)

TGS50 series electrochemical type CO gas sensor launched

To meet market requirements for battery operable and high accuracy CO sensors, Figaro’s first electrochemical CO sensor was developed and released, bringing further market share expantion in the North American CO detector market.

The first catalytic type gas sensor

Surface-mount type ultra-miniature MEMS sensor for air quality

Low power consumption and battery operable MEMS sensor for combustible gases

Ultra-miniature electrochemical type CO sensor

Combustible gas sensor module using TGS6812

The first and world's smallest class NDIR CO2 sensor

Refrigerant gas sensor module using TGS26 series

TGS68 series catalytic type gas sensor launched

There was a need for catalytic type gas sensors in addition to MOS-type gas sensors in order to further expand the customer base in Japan and overseas in the field of combustible gas detection. As a response to such need, the catalytic type gas sensor was developed and launched.

Awarded the Grand Prize of Technology of Japan Gas Association (JGA)

Figaro received the Grand Prize of Technology of Japan Gas Association (JGA) for ”Development of commercial ventilation alarm”.

Breath alcohol tester "FUGO" launched

In 2011, it became compulsory in Japan for the passenger transportation industry to conduct breath tests with alcohol testers when departing and returning from work. Since then, new models of breath alcohol tester "FUGO" series have been developed and released in response to changes in market requirements.

Miniaturized and highly functional breath alcohol tester FALC series for commercial application

Riken Figaro, Inc. was absorbed into Figaro Engineering Inc.

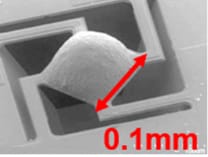

TGS80 series MEMS MOS type gas sensor launched

Further miniaturization and low power consumption of MOS type gas sensors were achieved through MEMS technology.

Gas sensing element of the MEMS sensor

Figaro Sensor (Shanghai) Co., Ltd. established

The subsidiary company was established in Shanghai, China, with the aim of strengthening sales of gas sensors to the Chinese market.

Figaro Sensor (Shanghai) Co., Ltd. (current photo)

Won "Supplier of the Year" award for 2014 from BRK Brands, Inc., USA

New Cosmos Electric Co. acquired major corporate shares of Figaro Engineering Inc.

East office added in Minoo city, Osaka to expand office and factory spaces

East Office

The 50th anniversary of the company

The Anniversary celebration

Selected as one of the Global Niche Top 100 companies by Ministry of Economy, Trade and Industry of Japan

Figaro was selected as one of the small and medium-sized companies that have secured a global market share of 10% or more for a specific product or service for at least one year within the past three years.

Established Figaro Europe Office in Germany